When companies originally set up multi-org in Oracle’s® E-Business Suite, security and control were the primary drivers for separating data into different operating units. Plants wanted to run their own operations, negotiate their own contracts with suppliers, and set up their own invoicing, inventory and receiving practices. Moreover, there was a competitive environment among different divisions, product line operations, and general managers. One part of the company did not want another part to see the transaction detail. Little attention was paid to maximizing the purchasing power of the entire enterprise to negotiate better terms and discounts with common suppliers. As a result, companies often set up hundreds of operating units, each with its own freight carriers, matching tolerances, approval hierarchies, pricing lists, supplier terms, and contracts.

It was difficult to determine how much business was conducted with a particular supplier, difficult to determine the enterprise cost of managing and maintaining different supplier relationships, and the burdened costs of different inventories.

Within a multi-org environment, much of the data is set up by operating unit. While there are some advantages to having a multi-org environment, especially in regard to security, there are limitations that prevent obtaining an enterprise view of the data, especially the ability to leverage supplier relationships. There are three primary areas that can be negotiated with suppliers that contribute major amounts of money to the bottom line for an enterprise:

- Obtaining larger discounts

- Changing payment terms

- Reducing the number of suppliers

The following examples illustrate the benefits of executing each of these strategies. In order to recognize the savings discussed, operating units need to be consolidated to provide an enterprise view of the data.

Obtaining Larger Discounts

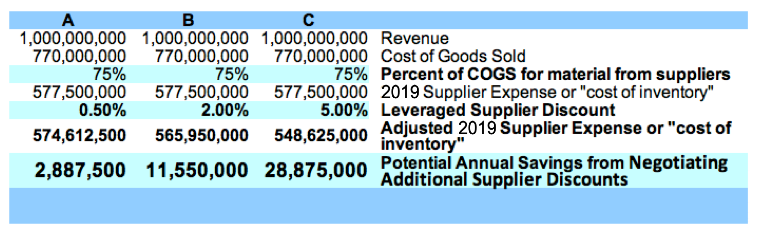

If you are able to determine how much you spend with each of your suppliers, you may be able to renegotiate your discounts. Many suppliers will provide volume discounts if you commit to certain spending levels. By looking at your total spend across all operating units, you may be able to reach the thresholds required for greater discounts. The following chart examines potential savings for increasing the supplier discounts by 0.5%, 2%, and 5%.

The data in the above chart includes an assumption that 25% of COGS (Cost of Goods Sold) is attributable to MRO (Maintenance, Repair and Operation supplies). As you can see, even averaging a half percent additional discount results in millions of dollars in annual savings.

Changing Payment Terms

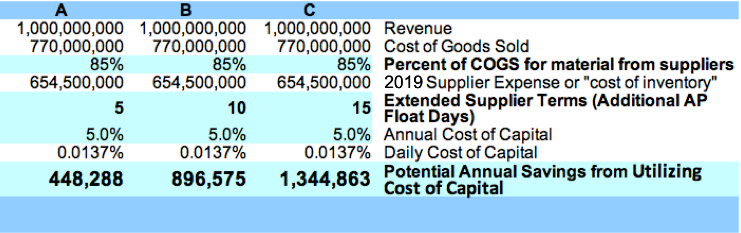

By increasing the number of days a company holds on to cash, additional interest will accrue, whether using a daily sweep checking account or another instrument for cash management. The chart below analyzes the benefits of extending the payment terms with suppliers and calculating the value of having the cash on hand for an additional “float” period.

This chart assumes the MRO portion of COGS is 15% and the annual Cost of Capital is 5%. Again, it is evident that negotiating an additional five days for payments results in hundreds of thousands of dollars in annual savings.

Reducing Number of Suppliers

There are a number of additional savings that might result from consolidating operating units or inventory organizations. Some of these are not as easily quantifiable, but result from obtaining an enterprise view of the supply chain operations when working with fewer suppliers in the enterprise. If you and your suppliers are closely aligned, operational savings occur because:

- You are able to consolidate distribution logistics (freight, receiving, inspections).

- There are fewer catalog items to maintain and reconcile among suppliers (Part # 100 from Supplier A is equivalent to Part # 357 from Supplier B).

- You work closely with a supplier so that the supplier knows what you need and when you need it. The supplier is tied into your system so that goods arrive on your production schedule. Handling just-in-time ordering through blanket purchase orders also saves time and money. The supplier, in effect, bears the inventory cost (both the value of money and the costs of physical storage, insurance, etc.).

- You can reduce inventory costs by eliminating duplicate or “dirty” data across operating units.

- Operational costs of working with a supplier including approvals, sending out RFPs, reviewing quotes, completing background checks, and making payments can be streamlined and result in significant savings.

- There are reduced legal fees since there are fewer contracts to negotiate.

In sum, there are many advantages to consolidating operating units. The financial benefits of having an enterprise view of the supply chain may outweigh the security factors that prompted the initial setup of E-Business Suites in a multi-org environment.